|

Henchman US |

|

|---|

Dual Color Tool Foam

Regardless of the industry you are working in, leaving your tools in an open area or in an area where multiple people have access to them throughout the day, can lead to misplaced or lost tools on the job site.

Not being able to find tools when you need them is more than just an inconvenience. The time spent looking for them reduces the productivity of your organization.

Tool Control makes it easy to identify which tools are in your tool storage (toolkit, roller cabinet or wallboard) or in use, and who is using them. This reduces the risk of leaving a tool behind and ensures all tools are accounted for at the end of a job or shift.

Henchman has 25 years of experience in designing custom toolkits with superbly fitting foam interiors for a large range of applications - allowing us to deliver a superior service, product and price. Many years of industry experience supplying a high-quality range of tooling coupled with in-house production of tool control foam inlays and laser etching, make us your ideal single-source supplier.

Contact us to discuss the tool control solution best suited to your requirements.

Visual Tool Control

The simplest solution suitable for every kind of company is Visual Tool Control with two-colored foam inlays - stationary, mobile and transportable sets, for everything from servicing atm machines and copiers, to maintaining and repairing mountain bikes, army vehicles, mining trucks, railway tracks and manufacturing facilities.

- Every tool has a unique tightly fitted slot in the custom-designed tool foam to make sure it can’t be put back in a different slot.

- The bright colored foam receives a contrasting top layer (normally darker). The contrast of the colors makes it obvious at a glance which tools are missing – if there is a bright empty slot, the tool is still in use.

- Laser Marking the toolkit number onto every tool makes it easy to identify which kit the tool belongs to.

- By tracking who a toolkit was issued to, the employee is responsible for returning the complete toolkit at the end of his/her shift.

- Broken or missing tools can be reported promptly and easily.

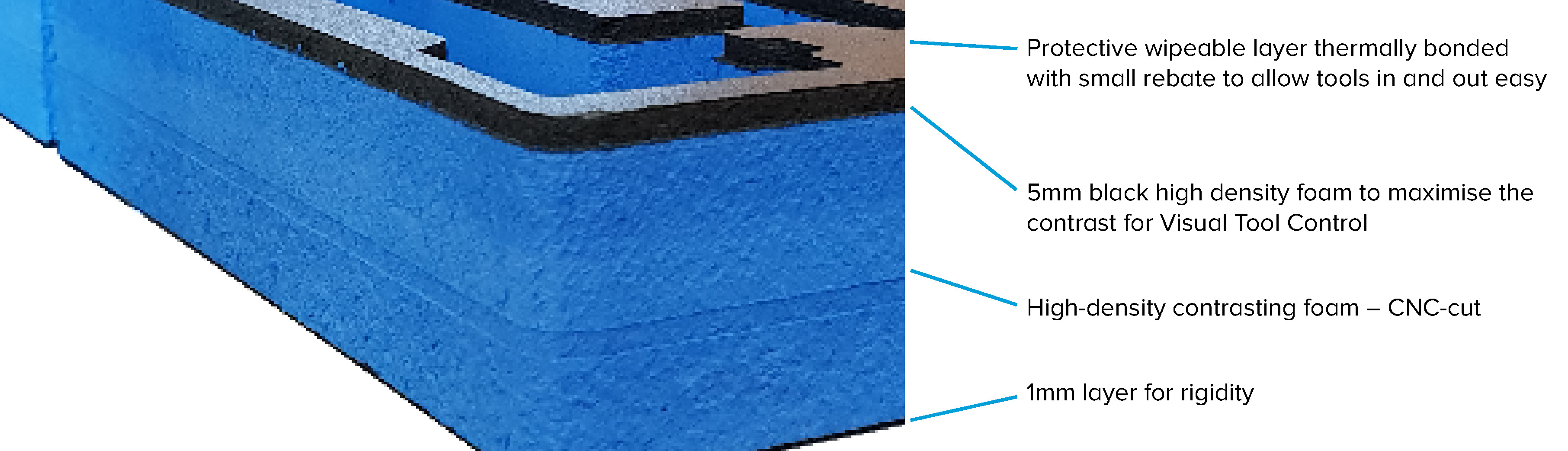

Henchman specializes in custom-cut foam inlays for Visual Tool Control. Our foam inlays have four layers: the bright-colored high-density foam receives a bottom layer for rigidity and a thin top layer of foam before the top layer is heat-bonded on. This top layer is very hard wearing, easy to clean and ideal for labelling or marking. It has a recess around every shape, to ensure that your tools and fingers do not get scratched, when picking out a tool.

Velcro Tool Tags

Adding Tool Tags makes it possible to track which of your employees is currently using a tool and is therefore accountable for returning it. Every technician has their own set of tags engraved with their ID number.

For Velcro Tool Tags, a Velcro dot is glued next to every tool cutout. The technician taking the tool needs to stick their tag on this spot before taking the tool and removes the tag when returning the tool.

Velcro Tool Tags are more commonly used on wallboards, but also possible in drawer cabinets.

Square Tool Tags

Square Tool Tags work the same as Velcro Tool Tags, but are square in shape and inserted into a small slot next to each tool.

They are more commonly used in drawer cabinets.

RFID and Barcode Tagging

Every tool is fitted with an RFID Tag or Barcode, that can be scanned to record the issue and return of tools and equipment. They are more commonly used as an inventory management system for larger items and whole kits stored in a Toolcrib.

RFID and Barcode scanning make it possible to electronically track tool movement, but require tool modifications, which can be a tedious job to initially set up, maintain (when receiving new tools), is not always possible, depending on the size of the tool and can be a source of Aviation FOD (foreign object damage), when a tag comes off.

Automated Electronic Tool Control

For Aerospace companies, CASR Part 145 requires suitable accountability of tools/equipment, suitable procedures to avoid FOD and correct calibration management of tools/test equipment within specified date requirements.

For Aerospace companies, CASR Part 145 requires suitable accountability of tools/equipment, suitable procedures to avoid FOD and correct calibration management of tools/test equipment within specified date requirements.

Electronic Tool Control for tool tracking reduces tool shrinkage, replacement cost and downtime due to lost tools. It offers centralized control of your essential hand and power tools. And it allows for customized badge access to storage units, provides an audit trail, and helps minimize the risk of FOD.

For more information on our various Electronic Tool Control Solutions visit henchmanTRAK.com

Benefits of Tool Control

No matter which style of Tool Control you decide on using, it will let you see at a glance which tools are in use and therefore

- Reduce time figuring out which tools are missing and keep up productivity

- Reduce risk of Foreign Object Debris/Damage (FOD) and follow the requirements of CASR/EASA Part 145 regulations

- Reduce the time and money spend on repairs/rework resulting from damage made by debris

- Help ensure a service technician arrives at a job with a complete kit to reduce the time spend at a job, therefore increase customer satisfaction, your reputation as a business, the number of recommendations and future business opportunities

- Help ensure the technician doesn't leave tooling behind and reduce the amount of money spend on replacing lost tools

Henchman has 25 years of experience in designing customized toolkits with superbly fitting foam interiors for a large range of applications - allowing us to deliver a superior service, product and price. Many years of industry experience supplying a high quality range of tooling coupled with in-house production of tool control foam inlays and laser etching, make us your ideal single-source supplier.