|

Henchman US |

|

|---|

A Guide to Intrinsically Safe Aircraft Maintenance Equipment

Jun 11, 2021 by MK Test Systems

A Guide to Intrinsically Safe Aircraft Maintenance Equipment

The aviation industry is rightly consumed with safety and accident prevention; this includes when the planes are grounded. MROs are working with aircraft that often contain fuel and need maintenance of electrical parts - a dangerous combination. These conditions require MROs to use tools which are classified as "intrinsically safe", but what does this mean?

What is Intrinsic Safety?

The aviation industry is rightly consumed with safety and accident prevention; this includes when the planes are grounded. MROs are working with aircraft that often contain fuel and need maintenance of electrical parts – a dangerous combination. These conditions require MROs to use tools which are classified as ‘intrinsically safe’, but what does this mean?

This article explains the term ‘intrinsically safe’ in the context of aerospace and the MRO environment. It will also explain the obligations upon MROs to use intrinsically safe equipment, and the potential consequences if incorrect equipment is used.

Your working environment implies risk from fire

Fuel, oxygen and a source of ignition must present in order for fire or an explosion to occur. Engineers working on commissioned – and therefore fuelled – aircraft are in an environment which is at inherent risk from fire.

What does the term ‘Intrinsically Safe’ mean within the aviation industry?

The term Intrinsically Safe describes equipment “which is incapable of releasing sufficient electrical or thermal energy under normal or abnormal conditions which may cause ignition of a specific hazardous atmospheric mixture in its most easily ignited concentration“

Equipment used near aircraft (i.e. in hangars) are subject to increased safety standards to prevent the possibility of fire and explosions. These locations are deemed ‘hazardous areas’ when there is the possibility of fuel or fumes to be present. This includes all areas along the hangar floor.

How is equipment designed to meet the ATEX/Intrinsic Safety Standards?

The electronic circuitry is designed to limit the electrical or thermal energy, by several methods:

- Current limiting

- Creating fused isolated areas

- Using overvoltage protection

- Minimising the amount of stored energy

- Reducing the amount of surface static on its enclosure.

When should Intrinsically Safe equipment be used?

For MROs working in aviation, the decision-making regarding the necessary equipment has been done for you. The hazardous zones are clearly defined, and only equipment classified for use within these zones should be used.

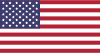

The Boeing Company specify the use of Intrinsically Safe equipment within the fuel vapour zones around airplanes and on fuelled aircraft. All equipment must be suitably certified for use within these zones to avoid the risk of spark ignition and the potential for catastrophic damage to personnel.

The below diagram displays the hazardous zones as determined by The Boeing Company.

Is Intrinsically Safe equipment more expensive than non-certified equipment?

In a word – yes. Electronic Equipment designed to operate in hazardous areas must comply to the ATEX Directive and must therefore meet the Harmonised Standards within this. In the case of an intrinsically safe design, costs will incur because of the additional testing requirement by an external notifying body. A company cannot self-certify because of the equipment’s intended use – in this case, Hazardous environments.

Although the components within the equipment are generally cost-neutral compared to standard equipment, the costs of the R&D programme and the process of obtaining the certification incur additional costs.

What are the benefits of using Intrinsically Safe equipment rather than purging aircraft of fuel?

Besides ensuring compliance with the AMM (Aircraft Maintenance Manual), there are several other benefits of using explosion-proof equipment for busy MROs:

- The number one point and of key importance is the fact that it helps to ensure a safe work environment and protects those nearby from explosion risks.

- Maintenance and diagnostic work can be performed without shutting down production and ventilating the working area

- Insurance premiums may be lower as a result of the risk reduction.

What are the different area classifications?

- Zone 0: An area in which an explosive gas atmosphere is present continuously or for long periods of time.

- Zone 1: An area in which an explosive gas atmosphere is likely to occur under normal operating conditions.

- Zone 2: An area in which an explosive gas atmosphere is not likely to occur under normal operating conditions.

- Non-hazardous: An area with very low risk of release of explosive or flammable gas; such as the propellant in an aerosol spray in an office.

For more information visit the MK Test website and read about the ExLRT Intrinsically Safe Loop and Joint Tester.