|

Henchman US |

|

|---|

Choosing The Right Borescope For Your Application

Nov 16, 2021

Choosing the right Borescope for your Application

There are numerous brands and models of Borescopes on the market, with a range of diameters and lengths. To help you choose the right Borescope for your application, we are explaining a few of the basic features.

What are Borescopes used for?

A Borescope is used to non-destructively inspect industrial systems and equipment for condition, manufactured parts for quality and security, and law enforcement for contraband, intelligence and safety.

Common inspections include internal viewing of:

- Turbine Engines

- Internal Combustion Engines

- Pipes

- Heat exchanger tubes

- Gear boxes

- Welds

- Foreign Object Retrieval

- Cast Parts

- Manufactured or machined parts

Borescopes can consist of

- Rigid rod or flexible tube to insert into the item under inspection

- Light source to illuminate the inside of the item under inspection

- Optical system that may consist of a relay lens system, rod lens system, fiber optic image guide a CCD or CMOS camera

- Eyepiece or Monitor to view the image

Rigid Borescopes

If your entry path is straight, a rigid borescope delivers excellent image quality and can be more durable and cost-efficient than other types of borescopes, such as fibreoptic or video borescopes.

If your entry path is straight, a rigid borescope delivers excellent image quality and can be more durable and cost-efficient than other types of borescopes, such as fibreoptic or video borescopes.

Rigid Borescopes are used to inspect machine parts, welded tubes, some castings, especially deep narrow bores.

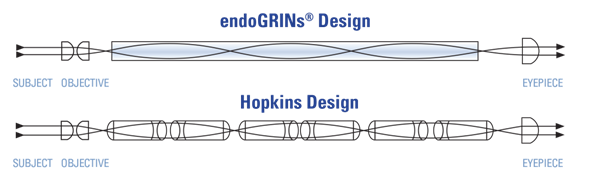

Rigid Borescopes use traditional, glass optics to relay the image. The heart of a rigid borescope design is the relay lens system.

Traditional solutions, like the Hopkins design, use many expensive micro-lenses and optical glass rods. The elegant simplicity of Gradient Lens Corporation’s patented endoGRINs® design make lens manufacturing and assembly easier and less costly, resulting in excellent optical quality at a much lower cost. The endoGRINs® gradient index lenses are the core technology of Hawkeye® Pro and Classic Rigid Borescopes.

Flexible Fibreoptic Borescopes

Flexible Borescopes are the best choice for a curved entry path and complex castings, such as engine blocks and heads, bent tubes, fuel reels and hydraulic lines.

Flexible Borescopes are the best choice for a curved entry path and complex castings, such as engine blocks and heads, bent tubes, fuel reels and hydraulic lines.

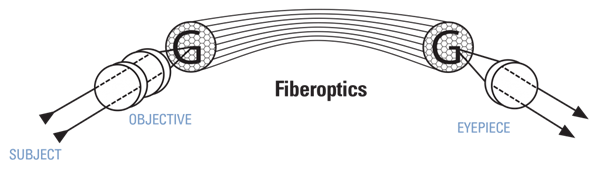

Fibreoptic borescopes use optical glass fibres to relay the image. The resolution depends on the number of fibres and their diameter. Each fibre forms a pixel in the final image. If your entry path is not straight, fibreoptic borescopes have the advantages of flexibility and articulation.

Video Borescopes

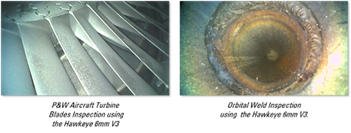

Video Borescopes are used for reliable and critical inspection of aircraft diesel and turbine engines without costly and time-consuming engine teardown, especially but not limited to Aircraft Maintenance and the Aviation Industry.

Video Borescopes are used for reliable and critical inspection of aircraft diesel and turbine engines without costly and time-consuming engine teardown, especially but not limited to Aircraft Maintenance and the Aviation Industry.

Power generation teams use Video Borescopes to inspect generators, heat exchangers, combustion chambers and turbine plates.

Manufacturers of castings and other complex parts inspect for voids, sand, flash, and other defects even inside complex parts.

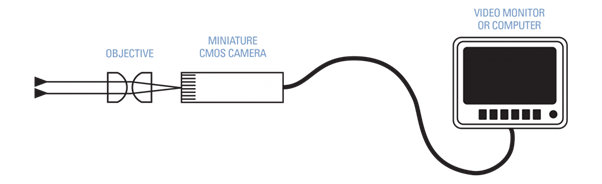

When compared with any other type of borescope, video borescopes deliver the best combination of image quality and convenience. Videoscopes transmit light through the objective lens to miniature video cameras, which then convey the image to a portable handheld monitor or laptop and desktop computers. When portability, still and video image capture, and image storage and documentation are key factors, a videoscope is the right choice.

Direction-of-View (DOV)

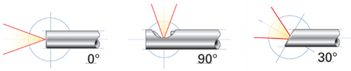

Hawkeye Pro and Classic Rigid Borescopes see straight-ahead (0°) and sideways (90°) with a mirror tube that slides over the borescope tube, making them two borescopes in one. The Hawkeye Pro Slim Rigid also offers a special dedicated 30° Direction of View scope using a prism.

Hawkeye Pro and Classic Rigid Borescopes see straight-ahead (0°) and sideways (90°) with a mirror tube that slides over the borescope tube, making them two borescopes in one. The Hawkeye Pro Slim Rigid also offers a special dedicated 30° Direction of View scope using a prism.

The mirror tube rotates the view over a full 360°, using the knurled knob. Our new mirrors are robust and durable for easy cleaning.

Field-of-View (FOV)

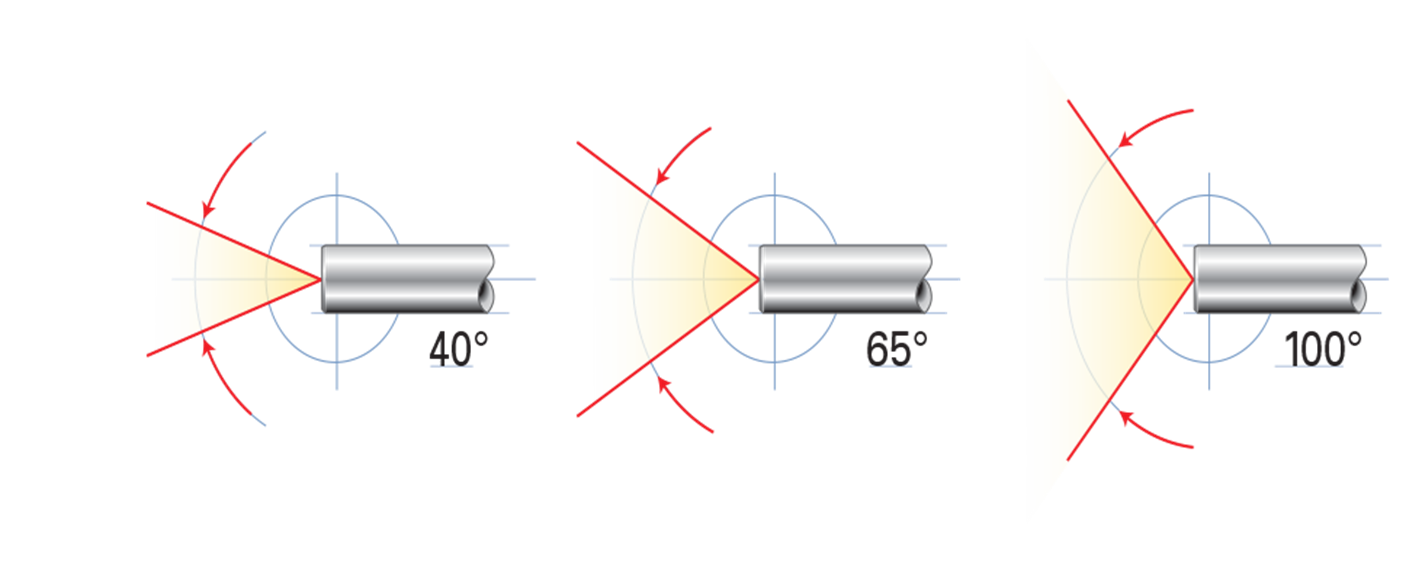

Most inspection situations need a “normal” objective lens (like a typical camera) with an angle of about 40°.

Wider lenses see more, but at a lower magnification, giving less detail. Magnification increases as the borescope approaches the subject, unlike a microscope objective, which gives a fixed magnification at one object distance.

Hawkeye® Borescopes

Hawkeye® offers over 80 models of either rigid, flexible or video borescopes with diameters between 0.5mm to 8mm and length between 2 inch up to 20 feet. Get the best quality for the most cost-effective solution!

Hawkeye® Rigid Borescopes:

Compared to other types of borescopes, Hawkeye® Rigid Borescopes have better image quality and are more durable and less expensive than flexible scopes. Hawkeye® Pro Rigid Borescopes have DOV’s of 0°, 30°, and 90°.

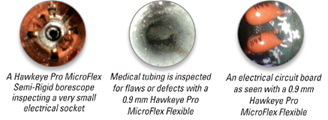

Hawkeye® Micro Flex & Semi-Rigid Borescopes:

Hawkeye® Micro Flex & Semi-Rigid Borescopes:

Hawkeye® Pro MicroFlex Semi-Rigid and Flexible Borescopes offer diameters as small as 0.5 mm, and a 10,000 or 30,000 fiber image bundle, all in “bendable,” semi-rigid, Nitinol or polymide sheath.

Hawkeye® Flexible Borescopes:

Hawkeye® Flexible Borescopes:

The Hawkeye® Pro, Classic, or Blue Flexible Borescope offer 0-way, 2-way, or 4-way articulation, up to 25,000 pixel image resolution, and flexible, durable, tungsten sheathing. Hawkeye® Flexible Borescopes are the finest fiberscopes on the market.

Hawkeye® Video Borescopes:

Hawkeye® Video Borescopes:

The Hawkeye® V3 HD Video Borescopes represent the next generation of fully portable, articulating, videoscopes. The innovative custom engineered image processor allows users to view or capture bright, crisp, clear images with lifelike colours. The servo driven articulation allows users to easily navigate even the toughest to access inspections.